HOT Search

Hot News

In the field of automotive safety, Tire Pressure Monitoring System (TPMS) is a kind of safety system used to monitor tire pressure parameters and automatically alarm when the tire pressure parameters are out of the reasonable range, which plays a key role in enhancing driving safety, comfort and energy efficiency.

Currently, Tire Pressure Monitoring System (TPMS) in the automotive industry is mainly divided into direct TPMS and indirect TPMS, among which, direct TPMS is the mainstream technology route in the automotive industry at this stage, which mainly adopts highly sensitive micro wireless sensing devices to collect real-time and accurate air pressure and temperature parameters of each tire and display them on the automotive instrumentation/central control screen in the form of visualized digital panels; when the tire pressure parameters are detected, they can be monitored and alarmed automatically, which plays a key role in enhancing driving safety, comfort and energy efficiency. When abnormal tire pressure data is detected, the system will alert the driver in the form of beeping or voice.

As we all know, when the tire pressure drops, the contact area between the tire and the ground increases, the friction and rolling resistance become larger, and the car needs to overcome greater resistance, which leads to increased fuel consumption and power consumption; while when the tire pressure rises, the tire contact area with the ground decreases, which reduces the grip and increases the skidding distance of the car when braking, and may also cause tire blowout accidents; therefore, letting the car maintain the appropriate tire pressure can not only increase the range of the car, but also increase the driving range, and may also lead to tire blowout. Therefore, maintaining the proper tire pressure can not only increase the range of the car, but also reduce the occurrence of safety accidents.

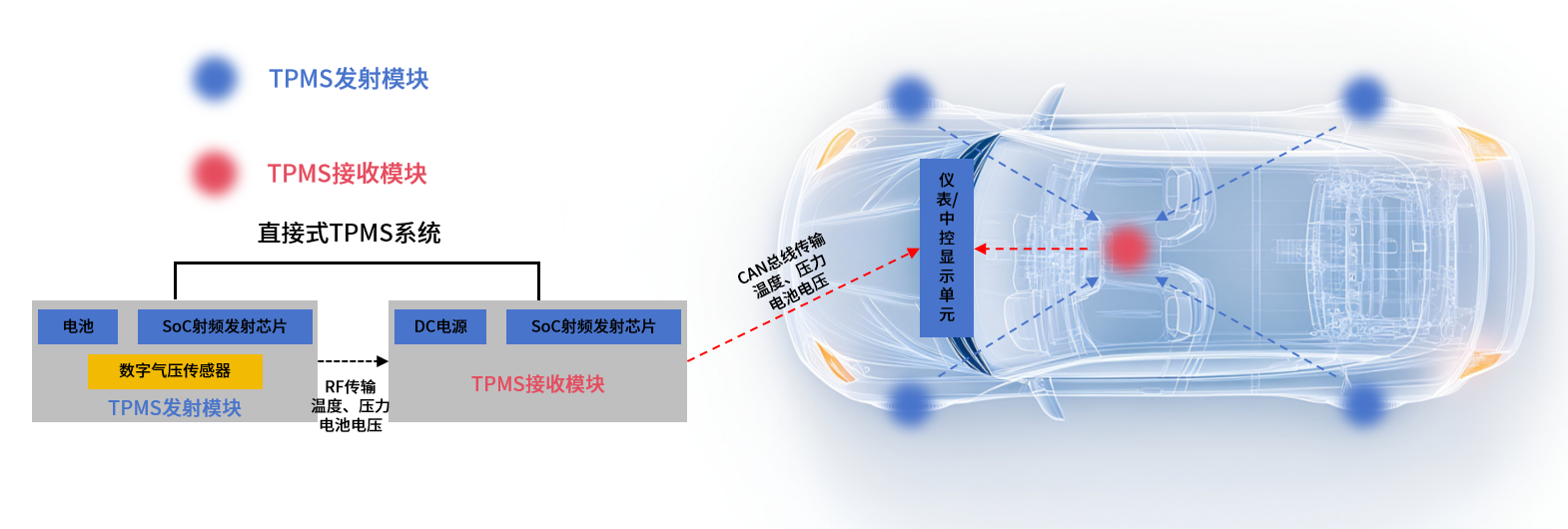

In a direct tire pressure monitoring system (TPMS), a digital barometric pressure sensor is the core sensing device to measure the air pressure, which is usually combined with a battery and a SoC RF transmitter chip to form a TPMS transmitter module and mounted on the inside of the hubs of the four wheels, or it can also be integrated with the tire valves, adopting an integrated built-in valve solution (a common solution used by the OEMs) .

Schematic diagram of a direct Tire Pressure Monitoring System (TPMS)

The TPMS transmitter module will transmit the data measured by the digital air pressure sensor and the battery voltage data of the module to the TPMS receiver module wirelessly in real time; the driver can view these data in real time through the instrument/center control screen to know the current condition of the tires, and the system will accurately identify the location of the tires and send out graphic, sound or text etc. within a short period of time if the temperature, pressure or battery voltage of a certain tire exceeds the alarm threshold. When the temperature, pressure or battery voltage of a tire exceeds the alarm threshold, the system will accurately identify the location of the tire and issue a low-pressure alarm CAN signal in a short period of time in graphic, sound or text.

It is worth mentioning that, as the core sensing device of TPMS system, digital air pressure sensor not only needs to work stably under complex automotive conditions (such as centrifugal force of high-speed rotation of tires, harsh temperature fluctuations, vibration of the driving environment, humidity and chemical corrosion, etc.), but also needs to be miniaturized, with low-power consumption and high precision and other key performance to ensure the accuracy and long-term reliability of the measurement data.

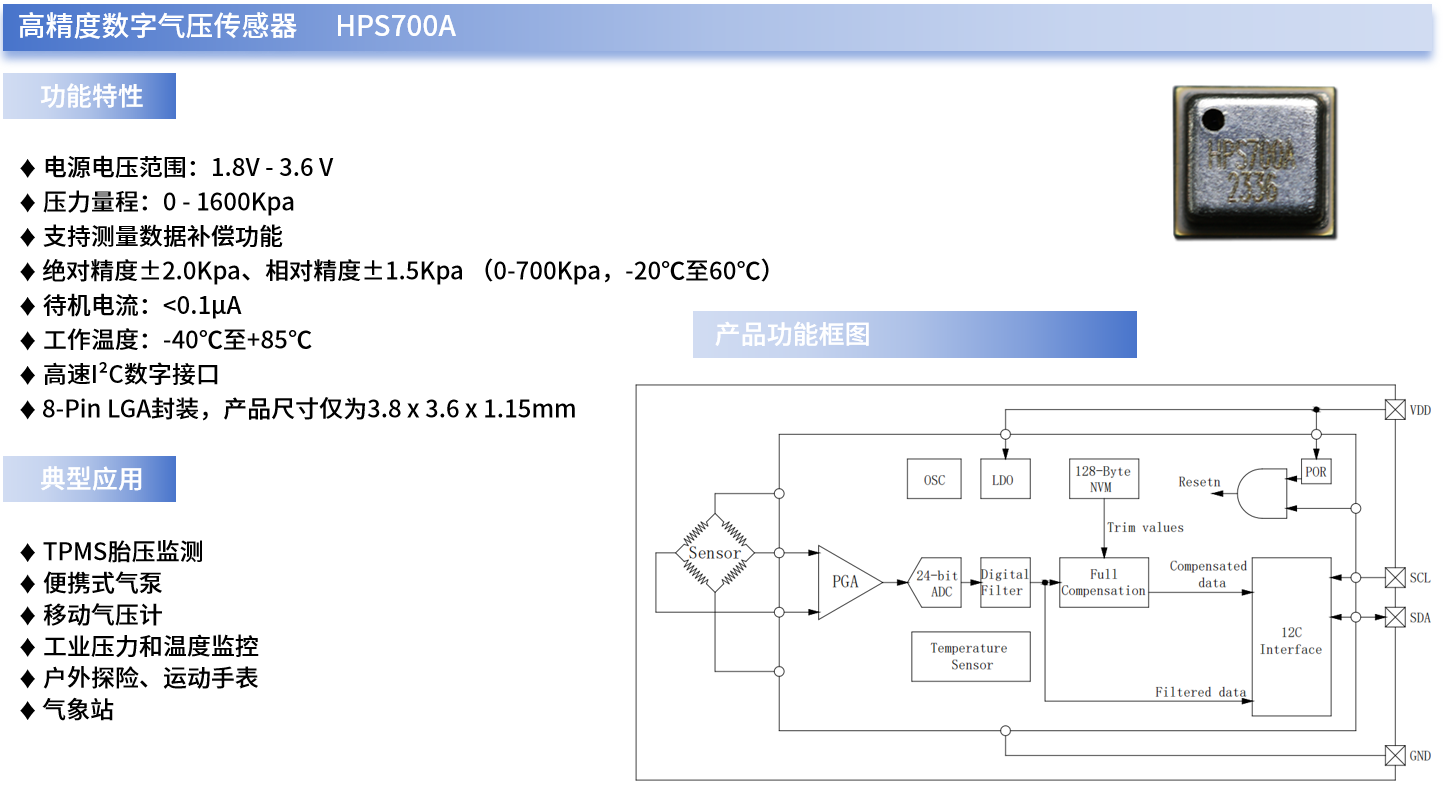

For example, the HPS700A developed by HOPERF is a high-precision digital pressure sensor with a high-speed I²C interface, which can provide real-time and accurate temperature and pressure measurement data at the same time, and its pressure and temperature data output is digitized by a high-resolution 24-bit ADC. In addition, the HPS700A has an internal integrated data compensation function (compensation by a dedicated algorithm), which reduces the workload of the external host MCU system.

The HPS700A pressure measurement has a relative accuracy of ±1.5kPa, supports wide temperature operation from -40°C to 85°C, has a range of 0 to 1600kPa, and its standby current is as low as 0.1μA, which can greatly enhance the endurance of the TPMS transmitter module.

The HPS700A is individually calibrated at the factory for both temperature and pressure measurement sensitivity and offset, and the calibration values are stored in the on-chip 128-byte non-volatile memory (NVM), so under normal conditions, users do not need to perform additional calibration.

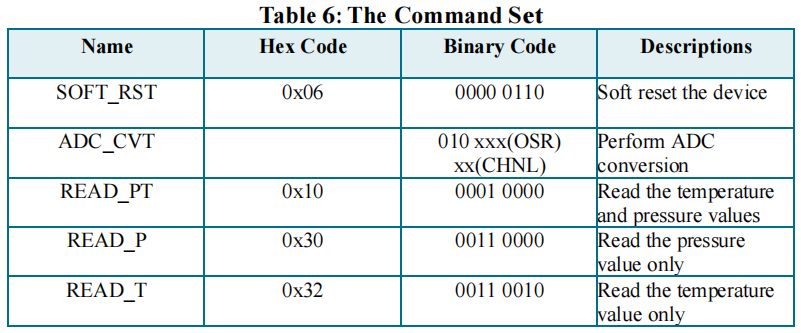

HPS700A-Instruction Set

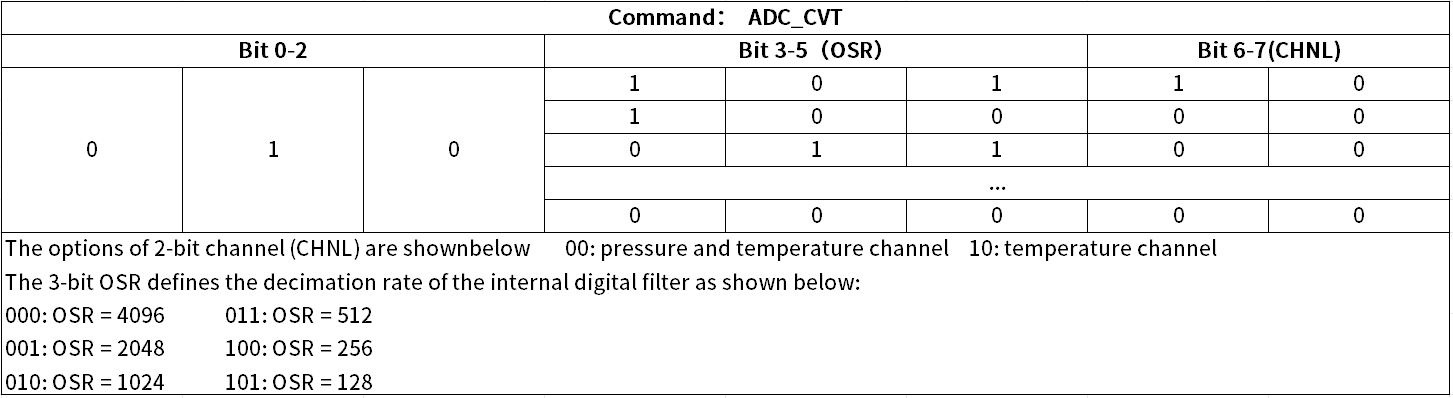

It is worth mentioning that the HPS700A also supports the user's host computer to read and write operations to the registers through the high-speed I2C digital interface to adjust the device's measurement accuracy and data conversion time, so that it can be flexibly adapted to the application scenarios under a variety of measurement demands. For example, by writing the ADC_CVT instruction (010, 3-bit OSR, 2-bit CHNL) to the registers, you can set the type of digital signal output from the sensor (temperature or temperature and barometric pressure) and its internal OSR oversampling rate.

When the 3-bit OSR is 000, the HPS700A oversampling rate will be set to 4096; when the 2-bit CHNL is 00, the HPS700A will convert the pressure and temperature channels simultaneously (i.e., the ADC will process the raw signals of pressure and temperature simultaneously to generate the corresponding digital output).

Note: The higher the OSR value (e.g. 4096), the more times the ADC samples and averages the raw signals, the higher the measurement accuracy (resolution), but the conversion time and power consumption will also increase. (For more details, please refer to the HPS700A datasheet).

Looking ahead, as the automotive industry accelerates its transformation to intelligence and internet connectivity, digital barometric pressure sensors, as the core sensing device in TPMS tire pressure monitoring system, will focus more on strengthening the multi-dimensional sensing capability and the in-depth fusion of intelligent algorithms in the direction of its technological development, and then promote the automotive safety monitoring from a single tire pressure parameter detection to the multi-dimensional state assessment evolution.